Enviro-foam Queensland specialise in the manufacture of polyurethane foam and this foam can be used for many different applications. Commercial products such as upholstery cushions, foam mattresses, custom cut shapes/sizes, foam sheets, buns and even car sponges.

Our range of foams range from 16kg/m3 to 40kg/m3 and includes flame retardant, fire resistant products tested to Australian Standards, slow recovery (or Visco-Elastic Memory foam and Gel Infused Memory foam) foam and sponge foams.

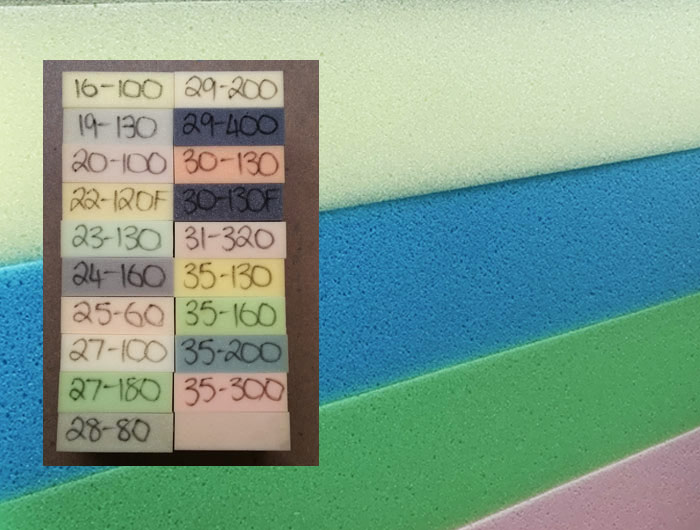

| Regular Foam | Premium Foam | High Resilience Foam | |||

|---|---|---|---|---|---|

| Density | Hardness | Density | Hardness | Density | Hardness |

| 16 | 100 | 25 | 60 | 35 | 130 |

| 19 | 130 | 27 | 100 | 35 | 160 |

| 20 | 100 | 27 | 180 | 35 | 200 |

| 23 | 130 | 28 | 80 | 35 | 300 |

| 24 | 160 | 29 | 200 | ||

| 29 | 400 | ||||

| 30 | 130 | ||||

| 31 | 320 | ||||

| Memory Foam | Fire Retardant Foam | Self Extinguishing Fire Guard III Foam | |||

|---|---|---|---|---|---|

| Density | Hardness | Density | Hardness | Density | Hardness |

| 38 | 40 | 22 | 120F | 32 | 60 |

| 30 | 130F | 32 | 120 | ||

| 36 | 100F | 32 | 160 | ||

| 36 | 140F | ||||

| 40 | 400F | ||||

We have the flexibility of being able to supply our product in sheet form, peel rolls, straight cut pieces or profiles cut to shape.

Enviro-Foam has a unique facility for manufacturing short runs of a wide range of flexible polyurethane foams and grades can be custom made by weight, hardness and colour for bun lot purchases.

Depending on the use of the foam, what surface it is being placed or used on, how often and how heavy the person using the foam is; will vary what grade of foam we would recommend best suitable. Please contact us via phone (07 3205 6088) or email (accounts@foam.com.au) for any enquiries.

BELOW ARE SOME EXAMPLES OF FOAM GRADES USED FOR SPECIFIC PURPOSES

Standard back foam – 16/100

Premium back foam – 25/60

Standard Seat Cushion Foam at 100mm minimum thickness – 23/130

Premium Seat Cushion foam at 100mm minimum thickness – 35/130, 35/160 or 35/200 depending on the feel your after

All our foam is made using the world’s best environmental practice in foam making. We do not add any extra fillers or extenders into our foam – No Solvents, No CFC’s, No Fillers, No Methylene Chloride and No added carbon dioxide. All foam is produced locally on site at our Clontarf factory on the north side of Brisbane.

STANDARDS

22/120F FOAM

Passed: AS/NZ 3744.1 (Cigarette burn test)

36/100F, 36/140F, 36/200F

Passed: AS 5852 (Flame Source 2)

Passed: AS/NZ 3744.1 (Cigarette burn test)

FIRE GUARD III MATTRESS

Passed: BSEN 597-1:1995 (British Standard 597-1)

Passed: BSEN 597-2:1995 (British Standard 597-2)

Passed: BS 5852-5:1982 (British Standard 5852-5)

Passed: BS6807:2006 Crib 7 (British Standard BS6807 Crib 7)

Passed: BS 7177:2008+A1:2011 (British Standard 7177)

Passed: AS/NZS 1530.3 1999

Passed: Airworthiness standards FAR Part 25 – 1995 Section 25.853 (12 sec ignition)